Reverse Engineering Services

Reverse Engineering has become a standard procedure for engineers in a wide range of markets. The technique is widely used in product development, production engineering, cost-down programmes and component refurbishing.

Why Reverse Engineering?

Mould Flow Services

Why the need for mouldflow analysis?

Mouldflow analysis can predict and identify potential tooling design issues, improve product quality, save costs and time caused by late tooling changes.

What we need to run mouldflow analysis:

3D CAD model (.iges, .step or any other CAD format files)

Material Property

What are your main concerns from the analysis?

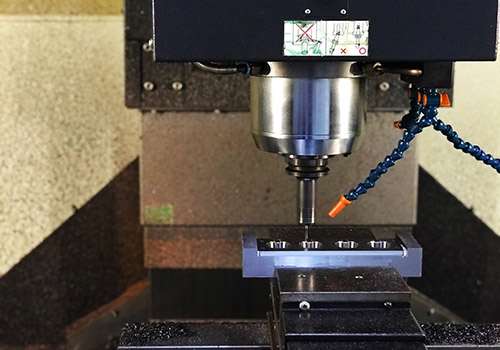

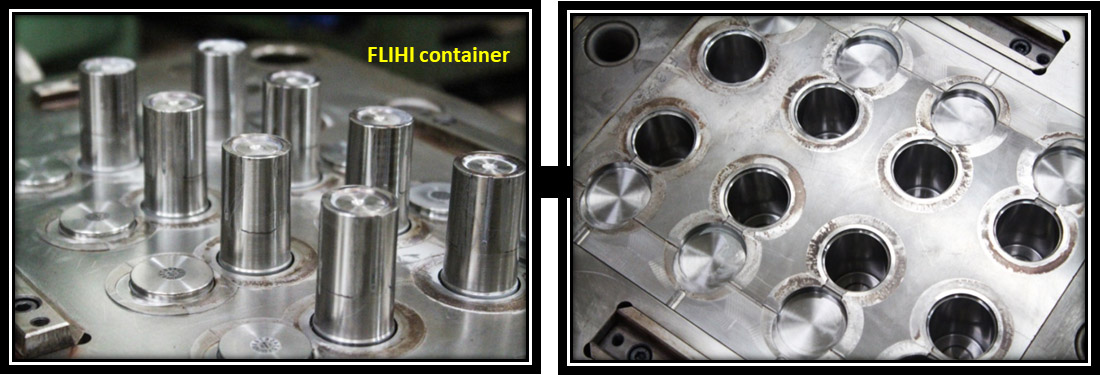

Mould Development Service

FliHi has more than 30 years of precision mould development experience. Founder James Wu said,” When considering the quality of a finished product, 90% depends on the mould design; the mould is a major factor affecting the quality of plastic injection products.”

Therefore, our talented R&D team has lots of experience helping clients’-conduct product development, product design and mould flow analysis. We can computer model and test actual prototype products to identify flaws during the design phase. This vastly reduces the time to deliver fully tested and finished products.

Development Process

Operation Process

Founder James Wu insists on using Stavax metal.